Insulation Test: How to Interpret Results

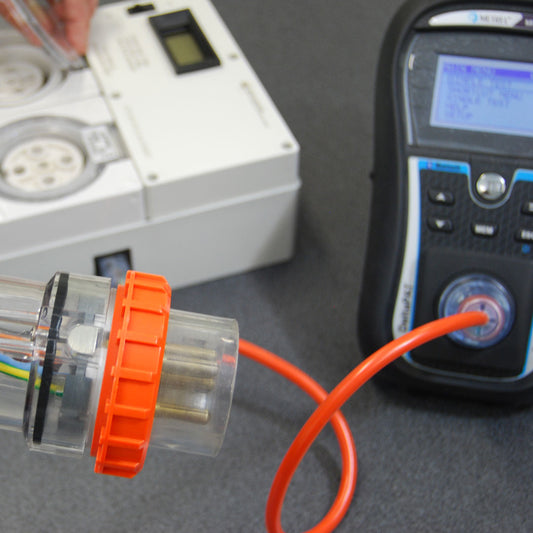

The Insulation Resistance Test is one of the most common and essential electrical tests performed. It assesses the ‘health’ of the insulation that prevents live wires from contacting each other - or us.

For instance, if water enters the wiring of an appliance, the test can reveal a complete lack of insulation resistance (<0.10 MΩ) or detect a much lower than normal reading, indicating compromised insulation.

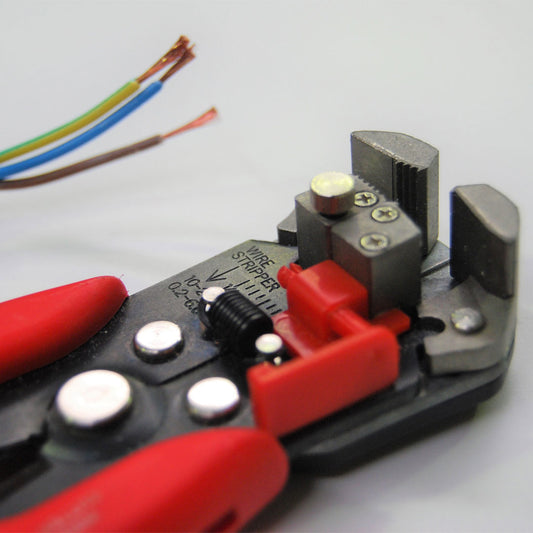

Another common scenario involves damage to the insulation caused by a flexible cord being crushed. Even if the outer insulation appears intact, the internal insulation covering the wires (conductors) could be compromised.

Older Appliances & Insulation Test

A low insulation resistance reading is often a warning sign that older equipment may soon fail. Over time, insulation deteriorates due to factors such as aging, exposure to water or oils, or degradation of plastic materials. When insulation fails for these reasons, the damage is usually not visible externally. However, when using a portable appliance tester, this test provides a reliable indicator that the appliance is nearing the end of its life.

Additionally, failing components, such as heating elements, can influence insulation readings. Appliances like kettles and refrigerators (with defrost elements) are particularly prone to these issues, making them useful examples of how wear and tear can manifest.

Changes in insulation resistance readings over time are key indicators of wear and tear. This highlights the importance of recording precise results and focusing on the actual measurements, rather than just relying on a simple pass/fail outcome. If you notice a lower than user insulation reading, it pays to go back and compare with previous readings as you might identify a trend and prevent a more serious fault occurring if the insulation fails completely.

Main Points to Remember for People Testing & Tagging

- Always record insulation resistance readings, not just pass/fail results

- Look for trends, as declining readings can indicate potential failure

- Internal damage might not be visible, so rely on test results

- Components like heating elements can absolutely affect results

- Regular PAT Testing helps keep track of wear and tear over time

Featured Courses

-

Face to Face Test & Tag Course

Regular price $499.00Regular priceUnit price / per -

Online Test & Tag Course

Regular price $469.00Regular priceUnit price / per$499.00Sale price $469.00Sale -

3 Phase Test & Tag Course

Regular price $249.00Regular priceUnit price / per -

Plug Top Replacement Course

Regular price $249.00Regular priceUnit price / per